Temperature Maintenance/Process Temperature Maintenance

Many raw materials and products will only remain in a liquid state if they are kept above a specific temperature.

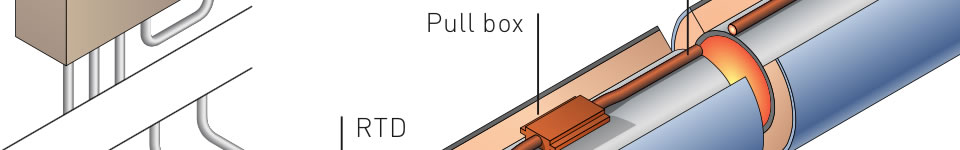

Electrical trace heating and thermal insulation provides the solution of maintaining the temperature of a product in a pipe or vessel ensuring that your process pipework and systems deliver your product to the point of delivery at the required temperature.

Read our information sheet on temperature maintenance and frost protection here.

When subjected to low ambient temperatures or ‘No Flow’ conditions, heat loss can cause the contents viscosity to increase. This can cause the material to harden or set within the pipework, either slowing down the process or causing problems to pumping equipment.

Temperature control is a vital part of the design, from local surface sensing capillary tube temperature control thermostats to electronic controllers with LED readouts accurately controlling the temperature of your product.

By utilising the correct type of Heating Cable, Thermal Insulation and Temperature Control, process pipework will operate efficiently for many years

To discuss your pipeline heating/Vessel Heating needs please contact us on 01484 859 700 or email us at sales@traceheatingprojects.co.uk.